We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

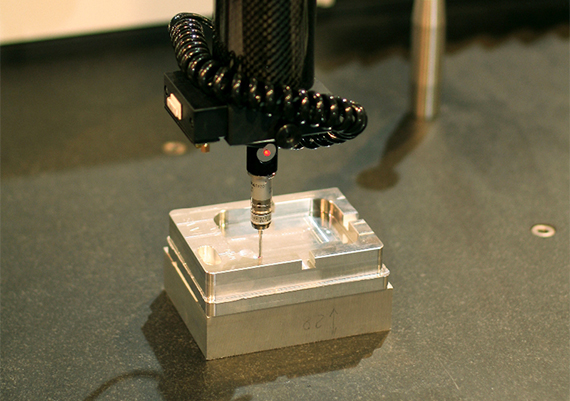

Our machines are inspected and maintained regularly to achieve the highest accuracy. We are also equipped with a Renishaw probe system within the machine which measures accurately within .0001'’. This gives us the ability to inspect all our items with high precision during production.

All items produced at Gottics are tracked through our ERP software from start to finish for complete traceability.

We can provide the material; heat treatment and full dimensional inspection reports for all parts. Inspection records are kept for up to 6 years at the customer’s request.

With our Mitutoyo CMM and the latest version of the software, you can be assured you will receive your part right the first time, every time.

All Gottics employees are equipped with regularly maintained high-quality precision measuring tools.